Line of industries – besides life science – Which industries, types of businesses, worktasks and integrated workflows would benefit from Scifeon? – check it out

Environmental & innovation laboratories

Regardless of whether you are testing water quality, soil conditions, work with solutions that can promote the green transition, or other environmental research work, then Scifeon is a tool that can help you in the daily workflow to reach goals faster. Innovation in any field would benefit from Scifeon – not just the green transition. The object of innovation is not relevant. The system gives you a safe and practical place to store your data on the day-to-day basis, and the modules, which are set up completely individually for each workplace, ensures that your data can be treated and analyzed until the results you need to achieve are brought to light. The system is likewise suitable for supporting innovation build upon the data provided from the research proces. If you need to report data to other either public or private partners, this can be done easily with Scifeon, as the system can be integrated into other systems. (Assuming that the providers of these systems will allow API access). No matter the circumstances, it is still easy to make reports with the outputs that you can extract from Scifeon.

Agricultural laboratories

Today, a major development is taking place in the food sector, which in many respects is linked to either the green transition, or to a general streamlining and improvement of food production, agriculture, cattle breeding, to plant-based food production, meat grown in laboratories, etc. Whatever it is that you need to find a solution for, Scifeon is suitable for supporting your processes. In a profession where any action can have large consequences for both populations, nature and the environment, it is extra important to keep track of the facts, processes and data. Scifeon ensures that all your documentation and data will be securely handled and stored in a professionally developed database, which you can rely on. The modules belongs to and are set up 100% individually and adapted to the needs of each company and agency. They support that you can form an overview efficiently and arrive at valid analyses, which you can then draw conclusions from. If there is a need to hand over data to external public or private actors and business partners, or actually exchanging data, you can do it easily and without difficulty through Scifeon, on the condition that the system providers of these players and partners allow API integration. Even if this is not permittet, it will still be easy to share outputs with Scifeon.

Chemical manufacturing

The processes in chemical manufacturing contain several elements, which makes Scifeon extremely suitable as a test data storage and processing system. The handling of chemistry requires monitoring and caution, as well as consideration for the health of the end user and the environmental impacts. From idea and development, which will often require a more or less research-related activity for a provision of correct data and knowledge, to the concrete manufacturing process, post-quality tests and ongoing investigations, measurements and monitoring, up to aftermarket treatment. Scifeon is suitable for handling all stages of the process and can ensure both data from each step in the process, and at the same time establish an overview of consequences from one stage to the next with the option to go back and adjust. An indispensable tool that can help you one step ahead in terms of innovation and give you a competitive edge, in the cases, where new products are to be developed.

Manufacturing of plastic, plastic products & components

Many of the processes in plastic manufacturing are about having control over measuring conditions, ingredients, wear resistance, transfer of plastic to the content that it must contain and therefore incoming knowledge of the impact of other substances on plastic, weather resistance and wear etc. – depending on the purpose for which the plastic is manufactured, as well as the consequences for the end user and for the environment. It is not so straightforward and it requires a lot of tests, knowledge, expertise and processes that lean closely on basic research. Scifeon is extremely suitable for supporting all these aspects in the process towards being able to deliver the right product. It is also super suitable for supporting ongoing innovation of new products, whether you look into your products with the scope of green innovation on your mind, competitiveness, new demands from the market or other external factors that can affect a plastic manufacturer’s necessary ongoing development.

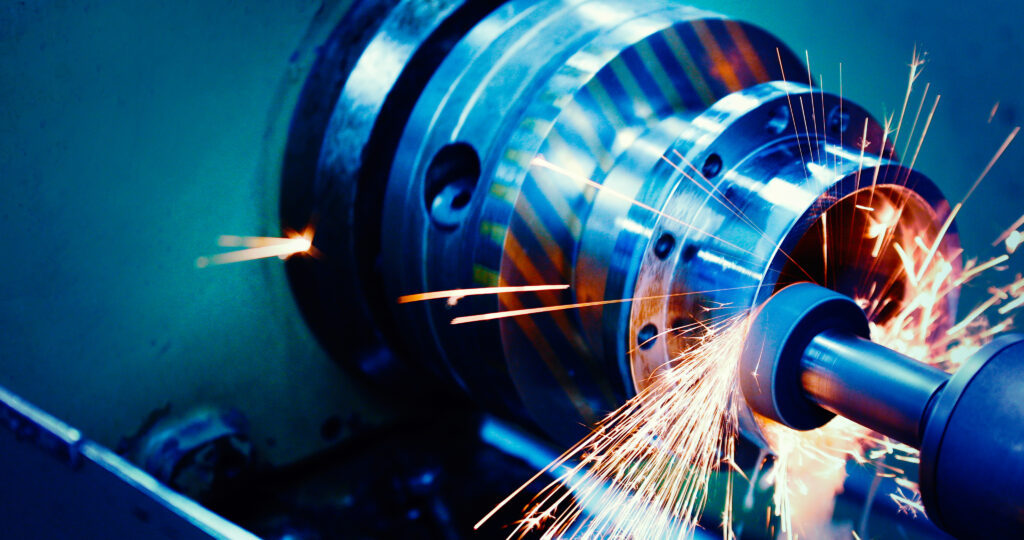

Manufacturing of metal, metal components & products

The manufacturing of metals is often dependent on precision, uniformity, the ability of the products to live up to the purpose for which they are produced, where e.g. properties such as wear resistance, rust resistance, fit, robustness and accuracy are critical to a product’s viability. Simultaneously society develops at breakneck speed, and what was good enough yesterday is not good enough tomorrow. What suited something in the past no longer fits. Depending on what you are making products for, it will for some companies mean that it may be necessary to constantly develop new ways and product adjustments without going overboard and compromise with your own credibility as a supplier. This requires that the product is always in order and can last and live up to its purpose. It requires knowledge. Scifeon is extremely suitable both for storing and processing the tests that are needed in the innovation and product development phases, as well as for testing of products on an ongoing basis.

Manufactoring of food, beverage and animal feed

The food and beverage businesses, and the production of animal feed, are some of the areas, where the most innovation and product development is happening, and at the same time one of the manufacturing processes that requires the most testing and monitoring, as the quality can easily be affected by errors and bacterial influences. Even the smallest influence can have major consequences in the end-user market, since what is produced, must be consumed into the body of humans and animals. It is also one of the most competitive areas, where new developments are constantly taking place and where the markets continuously make new demands on the products. The legislation also makes many demands, and new ones are added continuously. Food and drinks are required do solve many needs at once in our days, and there are many placings in the market. Likewise, is it an area with many niche companies that often create trends that can end up influence market demands. Other societal conditions come into play, including the green transition, and you always have the critical consumer to account for. Science and food manufacturing very often go hand in hand, or innovation (in pure form or as an offspring of science), and food production becomes two sides of the same coin. There is therefore a huge area in this industry, where the processes interfere with each other, which makes Scifeon an extremely suitable tool for everything from bridging the gap between research and manufacturing, – linking from farm to table via research intermediary – to become the companies’ own tool for ongoing documentation and data storage, as a basis for your own ongoing innovations, development and adjustments. By consistently used, Scifeon is also a tool that can increase competitiveness.

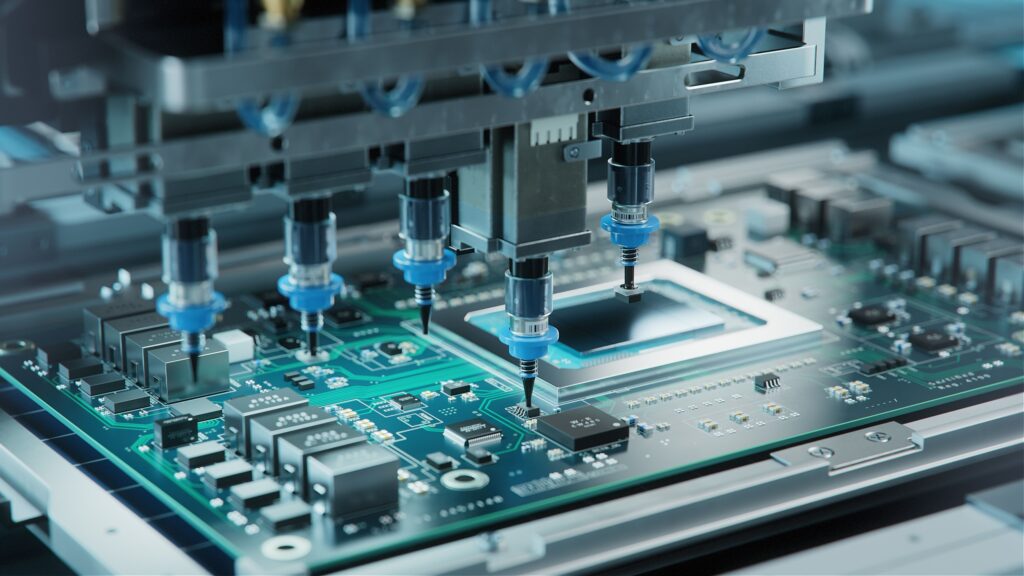

Manufacturing of electronic products

Manufacturing electronics requires great insight into many aspects of getting a finished product out of it, which works, isn’t a threat to the environment, isn’t damagable to the user, can work for its purpose, or can function as a reliable component in other electronics. As with the other forms of manufacturing, it is a constant challenge these days for manufacturers both to live up to the development in general, including especially the technological development, to keep pace with this and to be one step ahead the competitors, at the same time as delivering something that lives up to all parameters in relation to functionality, safety and durability (quality). Often many manufacturers of electronics have their production outsourchet or selfplaced in the East. It can be difficult to keep track of the quality and processes. Scifeon can be the tool that ties it all together for you. The system can be used both for your knowledge part in the exploratory test phase towards the innovation of new products, storage of externally acquired knowledge and then utilization of this in a scientifically safe and innovative way, over to store documentation on your test data, including having it implemented in that part of your production, which may be outsourced to external partners, or just located under your authority at a distant location.

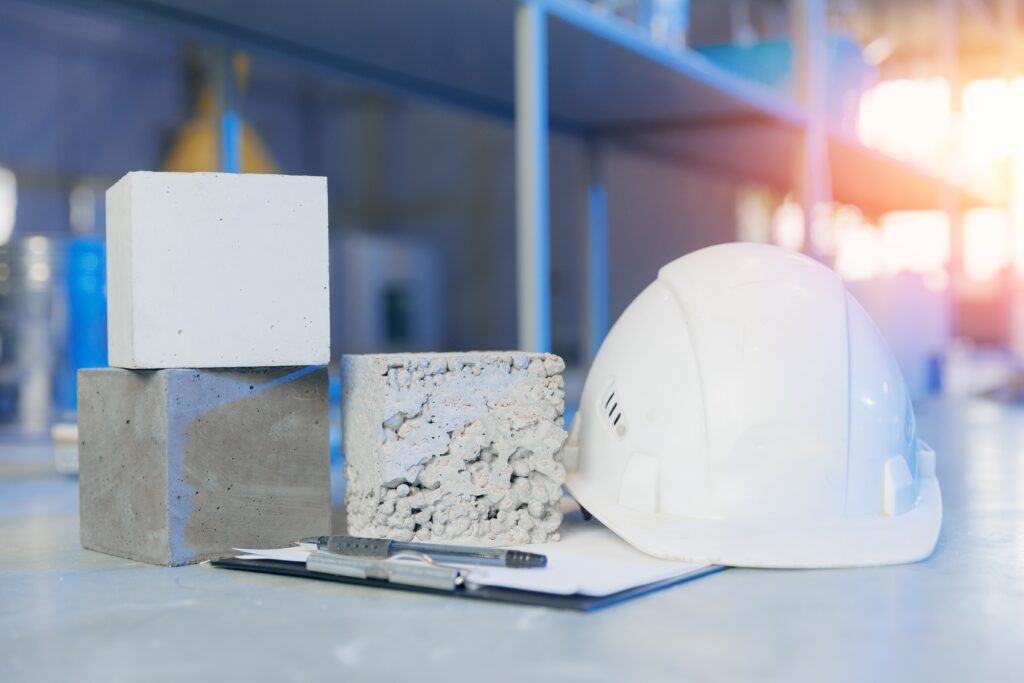

Manufacturing of building components

A large part of all new construction today is built in concrete. Concrete is not just concrete. Just ask the people, who work with it. Most major concrete manufacturers have their own laboratory, where the concrete is continuously tested. Both in relation to ensuring quality and to develop new products in line with the knowledge, which is provided and developed. The market and the law also continuously make new demands. But it is, regardless of the time for the production, very decisive, whether the concrete elements that are produced, can hold their own purpose. It can make huge impacts, if the concrete does not live up to the purpose of it’s placing. Worst case scenario, it can mean cracks in construction at height, or buildings, stadiums, warehouses, car parks, etc. which cracks and crashes. If you have a laboratory, then Scifeon is the perfect solution to deal with your test data. If you don’t have your own laboratory, but you do quality testings and work with product development on an ongoing basis, then Scifeon is also suitable for both storing your hardcore basic data, as well as the innovative part, and to have the two sides of the matter linked together. For building elements that are produced in other materials than concrete, the same advantages apply and you can get the same benefits from applying Scifeon to your workflow.

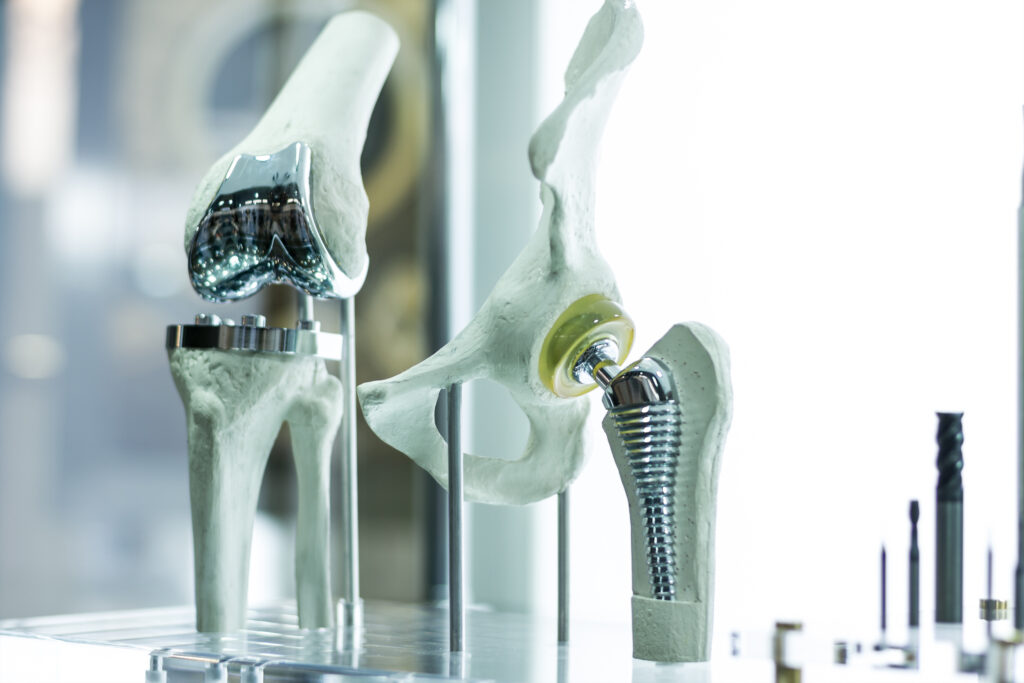

Manufacturing of personal aids

In order to be able to manufacture personal aids, it is mandatory that all one’s processes are based on research. Both beforehand and to a greater or lesser extent continuously during production. Personal aids are one of the areas in manufacturing that leans most closely on medical research and the finished products are often closely related to actual treatment, as they are produced to alleviate physical problems and challenges. To ensure that they work for their purposes and at the same time are safe to use for people in need of these tools, (so they prevent instead of adding harm to harm), then it puts the developers and manufacturers of personal aids in quite a quandary demanding field. If you don’t have your own laboratories, then most of the manufacturing companies as a minimum require either close collaboration with a research team or the knowledge and data from a research team, on which the manufacturer then bases its work from idea to final development and manufactured product. The target groups for most personal aids are the vulnerable, often the elderly and/or chronically ill people, or people with either temporary or permanent disabilities or functional abilities. The spectrum covers everything from hearing aids and personal emergency calls, to orthopedic solutions, prostheses and wigs. The production of personal aids often requires a close collaboration with the user and an adaptation to the individual user, while others are more scalable to larger volumes, which can subsequently be adapted personally. This applies, for example, to hearing aids, which must both solve a physical challenge that is close at hand level with a medical cure for a physical defect, and at the same time must be able to live up to a lot of quality requirements regarding the user’s safety, durability and competitiveness against other providers in the market. As with all other technological developments, the development in particular electronic personal aids and in some cases AI-based personal aids, the latter becoming a larger and larger part of the first. Scifeon’s research part, and documentation part make the system extremely suitable for both the innovation of and coupling this with the research basis, and the post-quality testing of products and solutions within personal aids.

Manufacturing of hygiene products

Hygiene products must be suitable for applying on our scin and hair, and at the same time be able to perform some advanced tasks. Since these are solutions and products that must be used on human physics, and in connection with human physics, it requires a large research base to be able to develop products within personal hygiene that solves their task without at the same time causing damage to the user. At the same time, they must have the intended effect. The entire spectrum of hygiene products ranges from the cosmetic to the caring through to the antibacterial. Common to all the products is that it requires extensive ongoing knowledge, development, new thinking on the basis of ongoing, new knowledge and post-quality testing of manufactured products to operate succesfully within this industry. The products which are produced are, in many cases, close to the medical field, as they have to come in touch with sensitive surfaces as skin, hair and nails. So the kinship with medical research and product development is not difficult to spot. Scifeon completely fits all the processes around providing knowledge in the form of ongoing research, or to incorporate already provided external research into your own manufacturing processes, to the development of new products, as well as the storage and processing of product testing data output after completion of manufacturing. The pretesting before manufactoring, during and after will have many similarities with actual, medical research work.

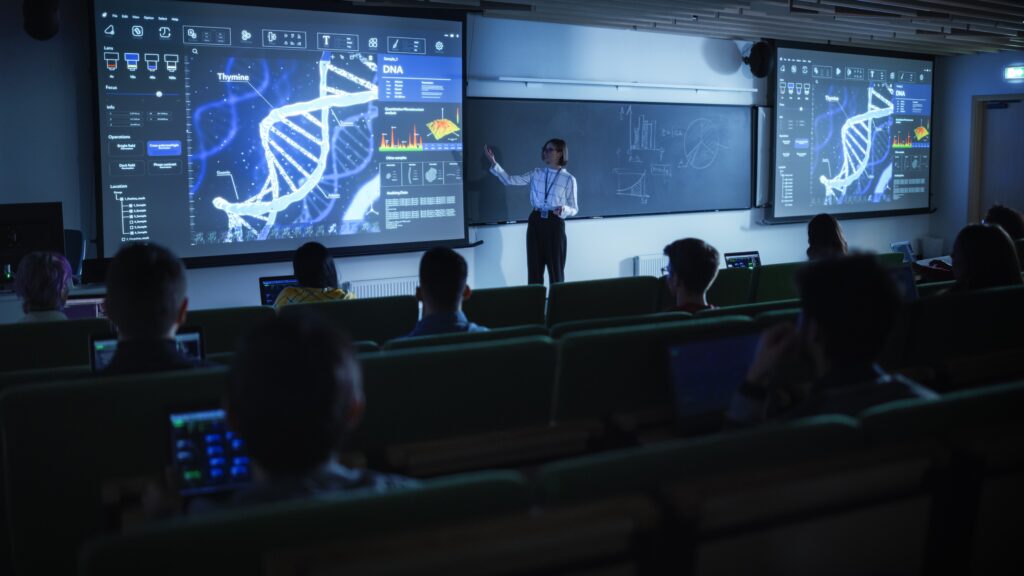

University Laboratories

Despite the system’s high level of development, the user interfaces and functionalities in Scifeon are easy to use and apply. This makes the system easy to implement for teaching purposes, without losing academically level. The system’s functions will also support that university researchers in collaboration with their students will be able to develop their projects and lead these to well-documented results through Scifeon. Scifeon is simply an indispensable tool for any educator and researcher, who would like to both achieve ground-breaking, new research results and at the same time be in control of data and documentation, whether the work takes place in part or in full teaching context or in a research facility on or off campus. If needed, it is easy to transfer data and results from the university environment to other bodies in society, which subsequently or in the process will need to use the results to work with or produce something from the acumulated research work and results.

Biotechnological manufacturing & Fermentation

Biotechnological manufacturing and fermentation intervenes in several ways in some of the other forms of manufacturing, including food and beverage manufacturing, which is also referred to in the above mentioned lines of businesses. Additionally, biotechnological research and production also covers over other advanced forms of production, such as when DNA research is used as a basis for developing new forms of treatment within e.g gene therapy. This is at the very heart of what Scifeon was originally developed for, and implementing Scifeon in all stages of biotech manufacturing would make a lot of sense. Scipheon is a system which in its hardcore core is a researcher and science system, and therefore is the processes within biotechnological manufacturing directly translatable with the system’s applications. Scifeon can perfectly fit in and become a natural, incorporated part of all sides of biotechnological manufacturing. The processes in producing biotechnological solutions are closely linked to continuous research and after quality measurements, as well as continuous inventions, which is the system designed to handle.